Automotive Die Casting Suppliers: A Guide to Quality and Efficiency

The automotive industry relies heavily on high-quality components to ensure the longevity and performance of their vehicles. One of the critical processes in manufacturing these components is die casting. In this comprehensive article, we will explore the role of automotive die casting suppliers and how they contribute to the fabric of the automotive sector. From the benefits of die casting to choosing the right supplier, we’ll cover everything you need to know.

What is Die Casting?

Die casting is a metal casting process characterized by forcing molten metal under high pressure into a mold cavity. This method is essential for producing complex shapes with high dimensional accuracy and a smooth finish. In the automotive sector, it is primarily utilized to create components that require precision and performance.

Benefits of Die Casting in the Automotive Industry

Utilizing die casting in automotive production offers several benefits:

- High Precision: Die casting allows for tight tolerances, ensuring that components fit perfectly in assemblies.

- Cost Efficiency: Once the mold is developed, die casting is cost-effective, especially for large production runs.

- Complex Shapes: The process supports the production of intricate designs that would be impossible or costly to achieve through other manufacturing methods.

- Material Versatility: Die casting can be used with a variety of non-ferrous metals, including aluminum, zinc, and magnesium, allowing manufacturers to select materials that best fit their applications.

- Reduced Waste: The die casting process is efficient, often leading to minimal material waste compared to other manufacturing methods.

- Improved Surface Finish: Components produced through die casting usually require less machining, which saves time and costs.

Key Components Produced by Automotive Die Casting Suppliers

Automotive die casting suppliers play a vital role in producing an array of components that contribute to vehicle performance and safety. Here are some common applications:

- Engine Parts: Housing, brackets, and other structural elements.

- Transmission Cases: Components produced for durability and precision in shifting.

- Wheel Hubs: Strong and lightweight designs for better vehicle handling.

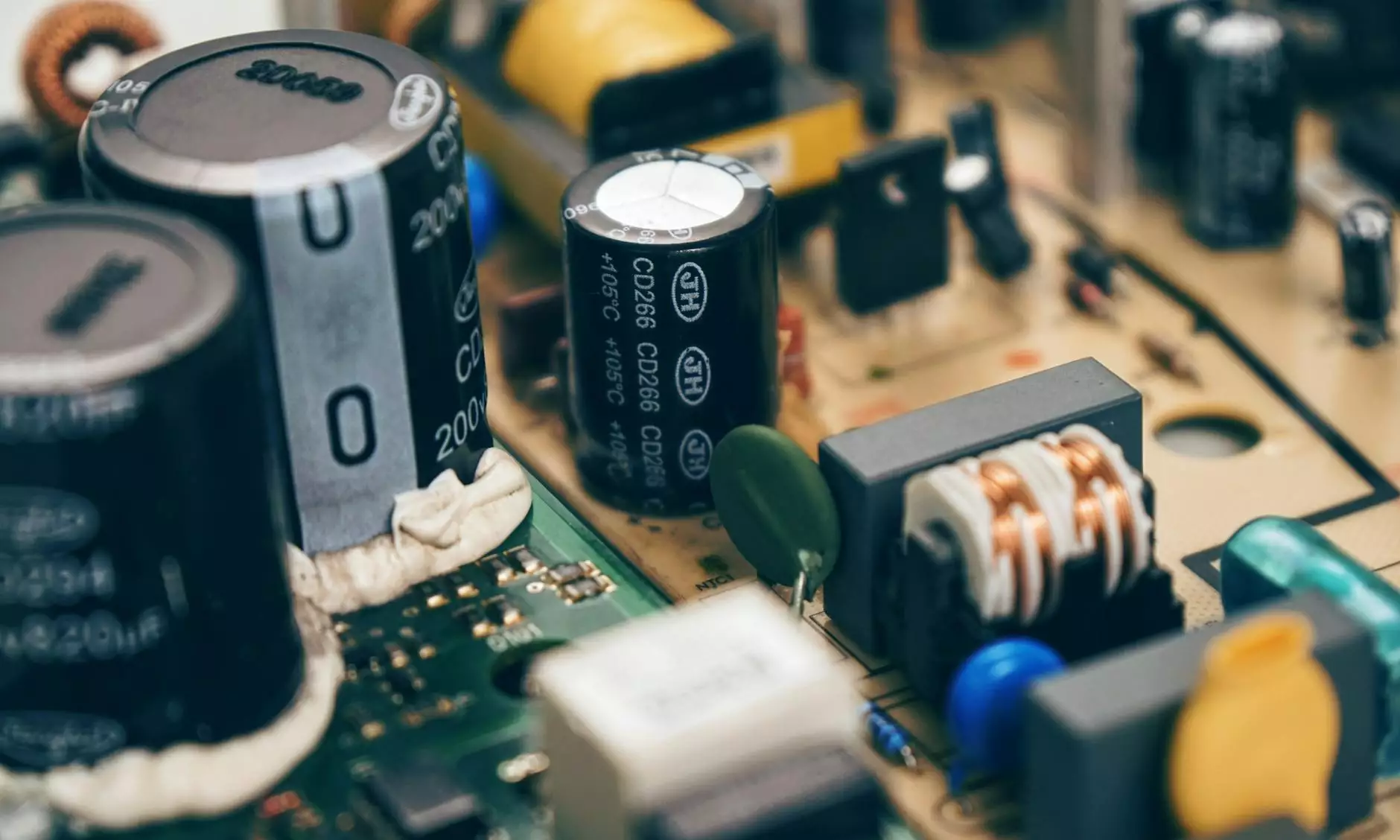

- Electrical Housings: Protecting electronic components within the vehicle.

- Heat Sinks: Essential for maintaining optimal temperatures in engine systems.

Choosing the Right Automotive Die Casting Supplier

With numerous automotive die casting suppliers in the market, selecting the right partner is crucial. Here are some factors to consider:

1. Expertise and Experience

When choosing a supplier, it is essential to look into their experience in die casting, especially in the automotive sector. A supplier that has a proven track record will likely understand the intricacies of the industry and can offer valuable insights.

2. Quality Assurance

Quality should be a top priority. Inquire about the supplier's quality control measures. Certifications like ISO 9001 can indicate their commitment to maintaining high standards.

3. Production Capability

Assess their production capabilities including their machinery, technology, and workforce. A supplier with advanced technology can often produce higher-quality parts more efficiently.

4. Customer Service

Good communication is fundamental. Ensure that the supplier is responsive and willing to collaborate to meet your needs.

5. Delivery Times

Timeliness can impact your production schedules. Discuss delivery timelines to ensure that they align with your requirements.

Trends in Automotive Die Casting

As technology advances, so too does die casting in the automotive sector. Suppliers are adopting innovative practices to enhance their processes:

- 3D Printing for Mold Creation: Suppliers are beginning to incorporate 3D printing technologies to create molds, significantly reducing lead times.

- Lightweight Materials: The use of lighter materials such as magnesium is becoming popular to improve fuel efficiency.

- Integration of Smart Manufacturing: Data analytics and IoT are increasingly being used for better quality control and production efficiency.

DeepMould.net: Your Trusted Automotive Die Casting Supplier

At DeepMould.net, we pride ourselves on being a leading provider of die casting solutions tailored to the automotive industry. Our commitment showcases itself in our:

- Expert Team: Our engineers have extensive experience in metal fabrication and die casting.

- Quality Standards: We adhere to stringent quality control measures to ensure every component meets the highest standards.

- State-of-the-Art Technology: Our advanced machinery allows us to produce complex shapes with precision.

- Customer-Centric Approach: We work closely with our clients to understand their unique needs and deliver tailored solutions.

- Fast Turnaround: We value your time and ensure timely delivery without compromising on quality.

Conclusion

As the automotive industry continues to evolve, the demand for high-quality automotive die casting suppliers becomes increasingly crucial. Understanding the benefits of die casting and knowing what to look for in a supplier can make all the difference in your manufacturing process. Partnering with experts like DeepMould.net can ensure you get the best components that add value to your vehicles and meet the stringent quality required in the automotive market.

Embrace innovation and quality in your automotive production by choosing the right die casting supplier. For more details about our services, visit DeepMould.net today!